With some, the material costs are so expensive that simulation of the cutting process is required because there is no second chance. Within industry, driving factors differ from shop to shop. Since Predator Virtual Machine behaves just like a real machine every improvement in CNC programming, materials, tooling, fixturing, and more, is shown graphically. Predator Virtual Machine’s ability to machine a part with accurate cycle times and then inspect it before a single chip is made provides manufacturers unlimited opportunities to improve their processes. Even remote learning of manufacturing processes is possible. With educational budgets being so tight, machine simulation can reduce maintenance, material and tooling costs. Educators can provide access to virtual machine experience without having to maintain physical machines or incur liability when trying to teach complex manufacturing processes. Within educational settings, machine simulation has become even more critical. This process significantly reduces trial and error setups and costly prove-outs. In addition, html-based documentation is automatically created for shop floor personnel. Machine tools stay up and running, and setup time is kept to an absolute minimum. Where most CNC users recognize the benefits of offline CAM, offline CAS provides identical productivity improvements. Using Predator Virtual Machine to perform CAS (or computer aided setup), the prove-out process is done offline. A library of 150 CNC controls that can be edited by the user, dramatically simplify initial configuration.

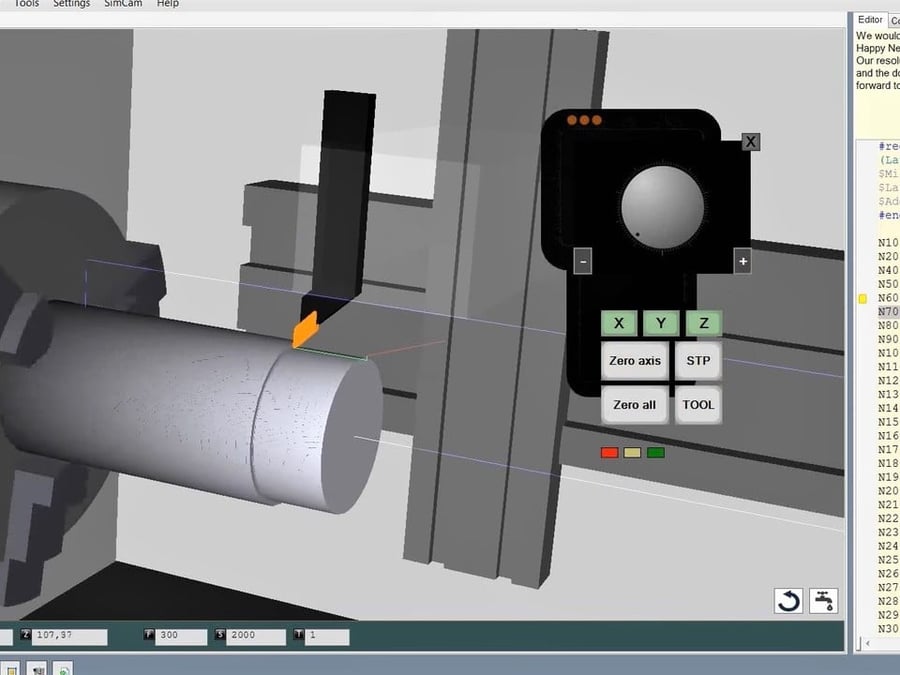

CNC specifics are configured down to the G-code & M-code level. A library of machine types such as VMCs and HMCs simplify the kinematic definitions. The machine’s base and moving parts are imported into Predator Virtual Machine and the kinematics are defined. By leveraging the strengths of today’s solid modelers, machine design is faster and easier then ever before. Initial setup requires the user to design a machine with any major CAD/CAM system. Unlike a machine tool, Predator Virtual Machine will safely detect machine crashes, broken tooling, CNC programming errors, and numerous other problems. A 3D virtual machining environment is displayed to the user with VCR buttons to control the simulation. It requires CNC programs, offsets, stock material, tooling, and fixturing details.

Predator Virtual Machine works just like a machine tool.

Predator Virtual Machine is designed to accurately simulate the CNC, the machine and the machining process. Predator Virtual CNC and Virtual Machine integrates CNC verification and machine simulation within a single Windows-based product. Virtual Machine - Machine Simulation & Verification

0 kommentar(er)

0 kommentar(er)